Karl-Heinz Bußbach

Head of New Energy

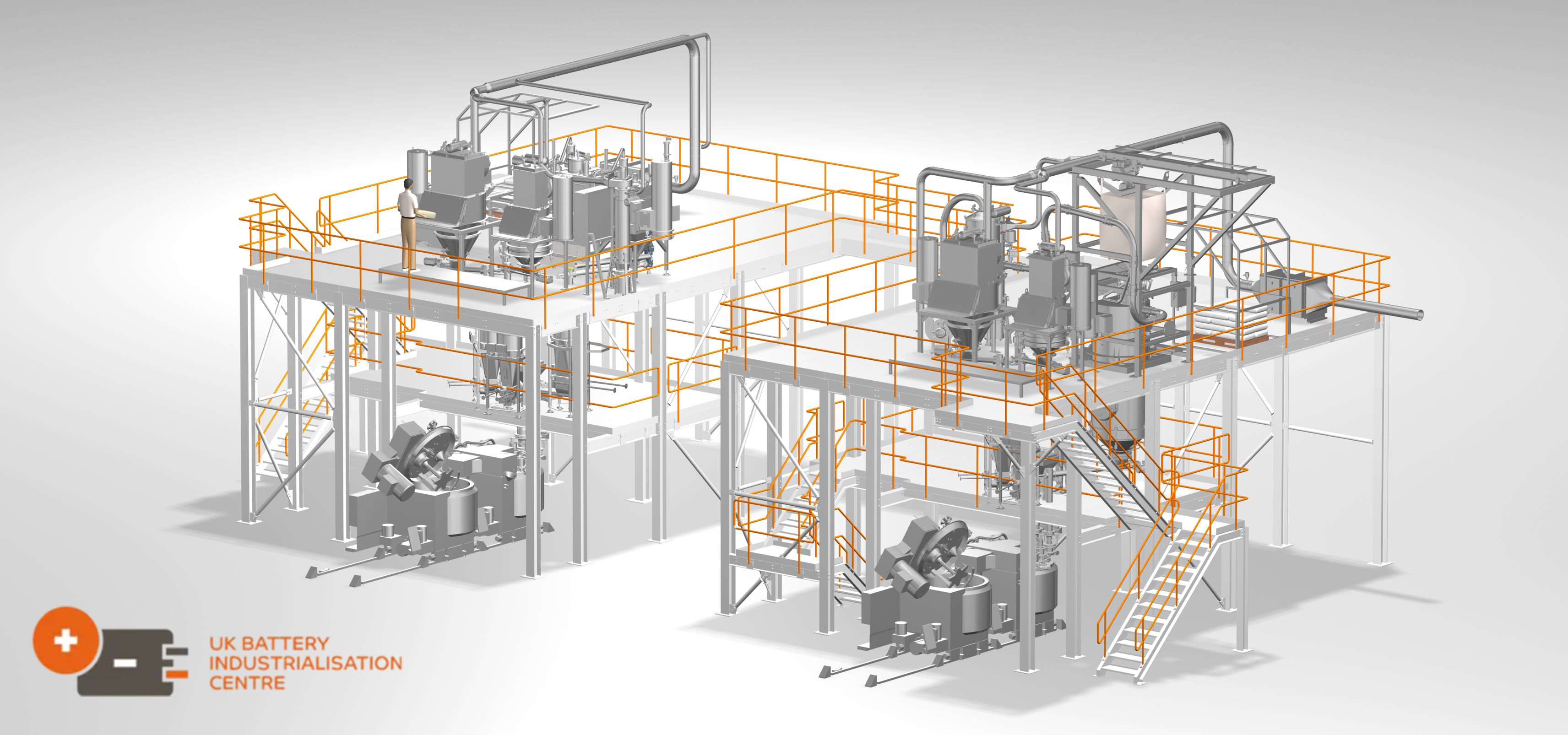

Battery production faces enormous challenges: Purity of materials, precise dosing, high production speed and the highest safety standards. As one of the world's leading suppliers of automation solutions for raw material handling, we offer you customised systems to meet these requirements. From the storage and discharge of raw materials to conveying, dosing and weighing, we are your reliable partner in every process step, always keeping the high demands of your production in mind. This enables us to optimise your production processes, improve product quality, reduce costs and increase safety.

AZO application areas New Energy: