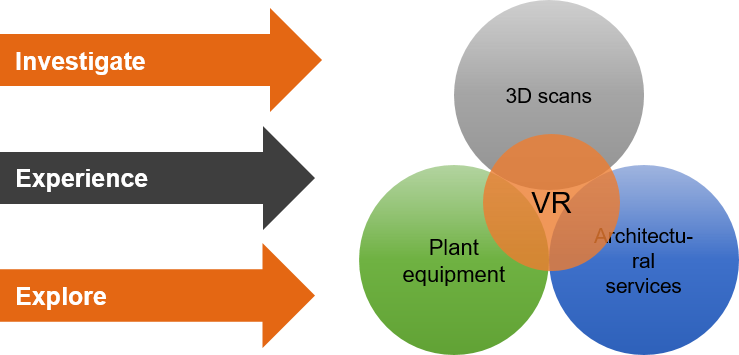

Owing to ever increasing enquiries and use of VR technology, AZO has three different types of VR goggles:

- HTC VIVE PRO SPEC (stationary, wireless version at AZO’s premises)

- HP Windows Mixed Reality headset (portable, wired version)

- OCULUS QUEST (portable, wireless version)

Each of these units has an associated Mixed Reality controller for movement, inspection and control in the virtual environment.

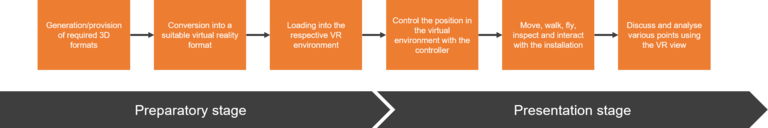

The models can in some cases be loaded directly into CMC ViewAR software or converted into the right format using various programs. Even the depiction of point clouds from 3D scans can in some cases be loaded directly and combined with our models.

To keep our customers safe during their individual VR tours, we use automatic boundary detection in the range of movement in order to avoid real-world obstacles such as tables and chairs.