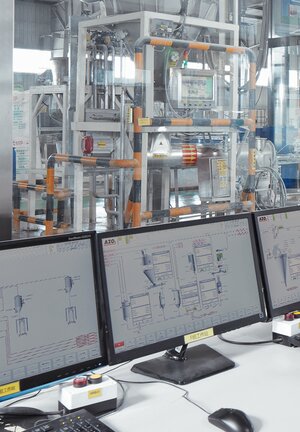

Without expertise in raw material analysis, plant engineering and automation, the transition from a previously purely mechanical process to raw material automation will not succeed.

The white paper explains what is important.

Automation in the bulk solids industry generally results in better and more consistent product quality. All processes can be reliably tracked, enabling faster fault analysis and avoiding downtimes. However, in order to automatically sieve, weigh, dose, store or discharge products, you need to know the bulk material precisely. This is why automation always starts with raw material analysis. Based on this, the best degree of automation can be selected - from the control of a single process step to a highly integrated, fully automated system.

Highlights of the white paper: