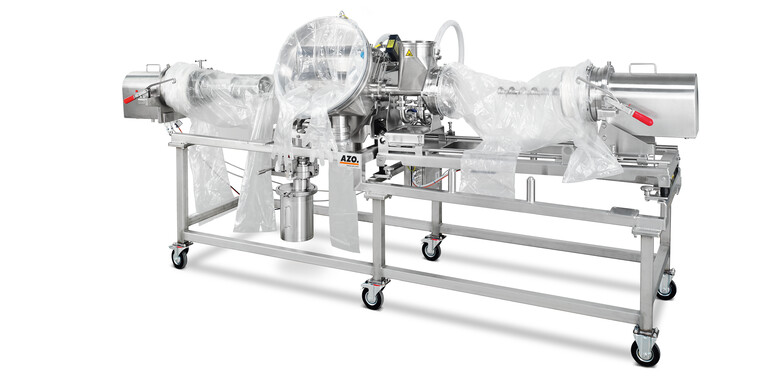

The DA ...Vario Containment screener is suitable for use in the bulk materials handling industry where there are very stringent requirements regarding the amount of residual dust released. This means the machine is suitable for screening toxic materials both in the pharmaceuticals field and also in other industrial applications. A risk to machine operators from dust that is harmful to their health can be ruled out, both in normal operation and in the event of a service job.

Special advantages

- Replacing the screen basket and dosing screw under containment conditions

- Inspection of the screen basket by opening the inspection hatch under containment conditions

- Outlay for operations wearing full body protection can be reduced

- Easy to exchange the dosing module for different performance ranges

- Technology for cyclone screener type DA proven over years of use

- No additional dosing unit is required thanks to self-dosing, resulting in low overall height

- The drive with rotor and screen basket can be pulled out and pivoted with quick-release fasteners

- The drive with dosing screw can be pulled out using quick-release fasteners

- Suitable for CIP

- Chromium-nickel steel design

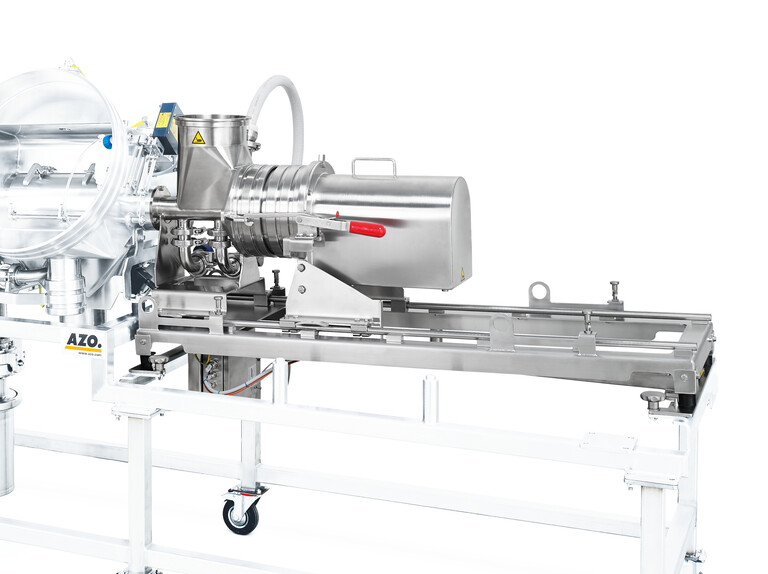

Dosing unit as replacement module

The dosing screw can be replaced inside the film liner under containment conditions. To do so, the appropriate tools are first passed into the liner beforehand.

The entire dosing module, consisting of drive, dosing screw, product inlet and extractor slide, can be replaced in order to attain different performance figures. To do so, it is separated from the rest of the screener using a changeover rail.